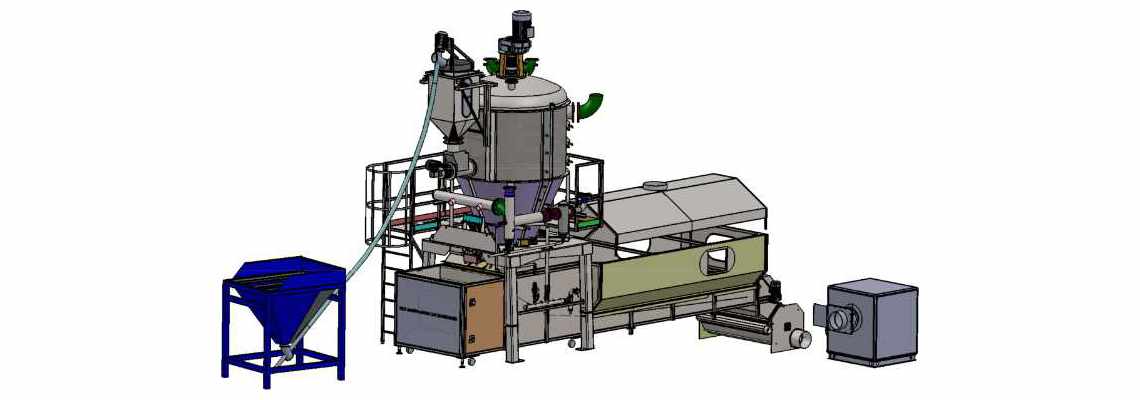

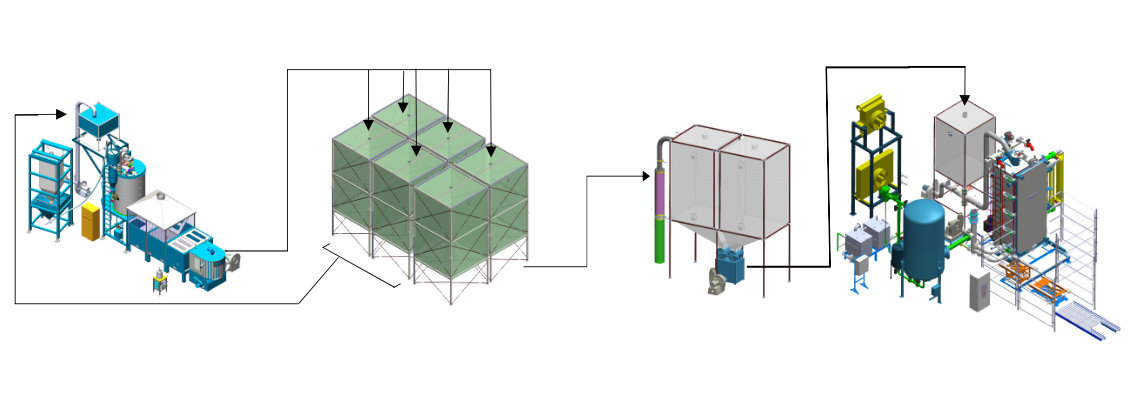

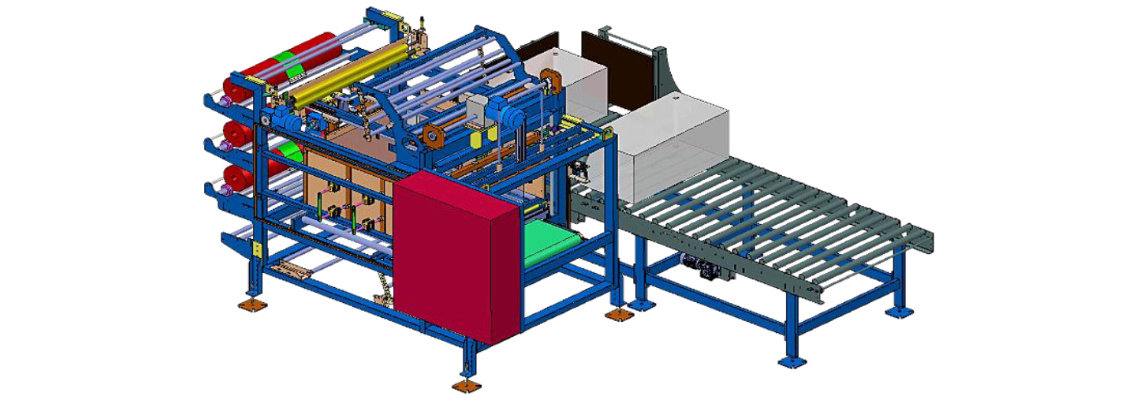

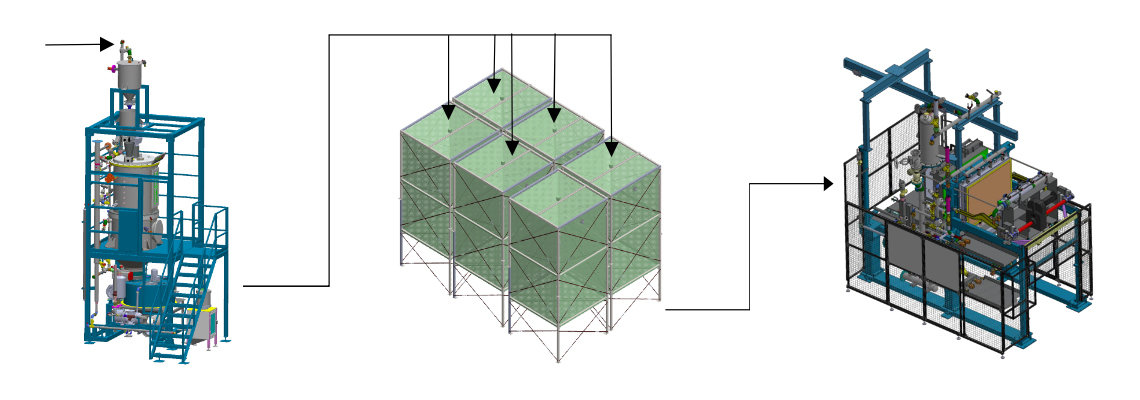

EPS PREEXPANDER DISCONTINUOUS

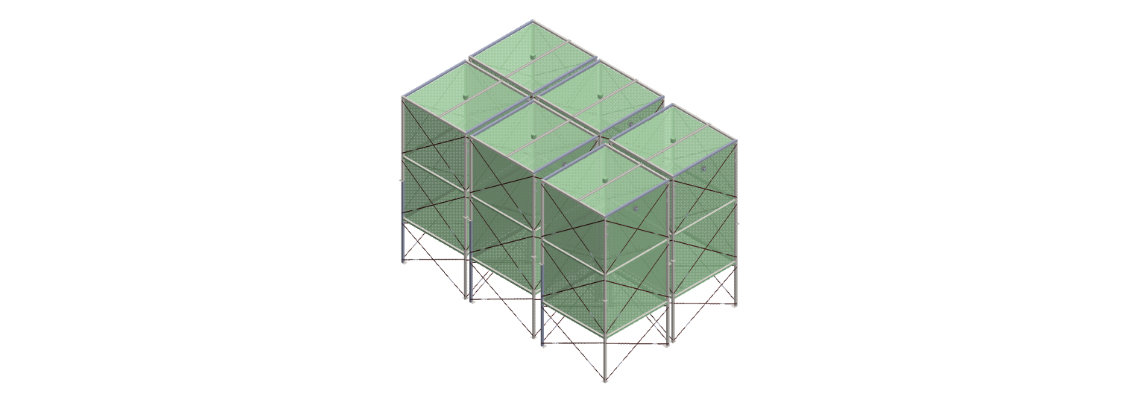

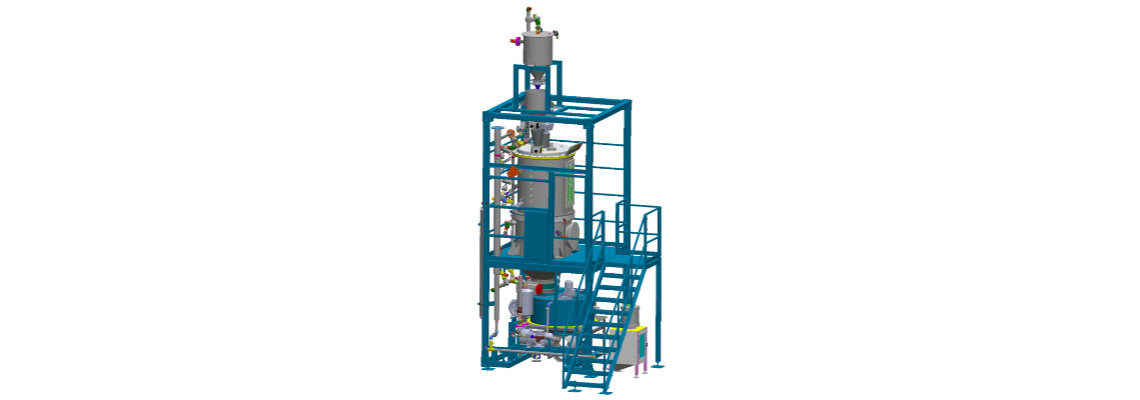

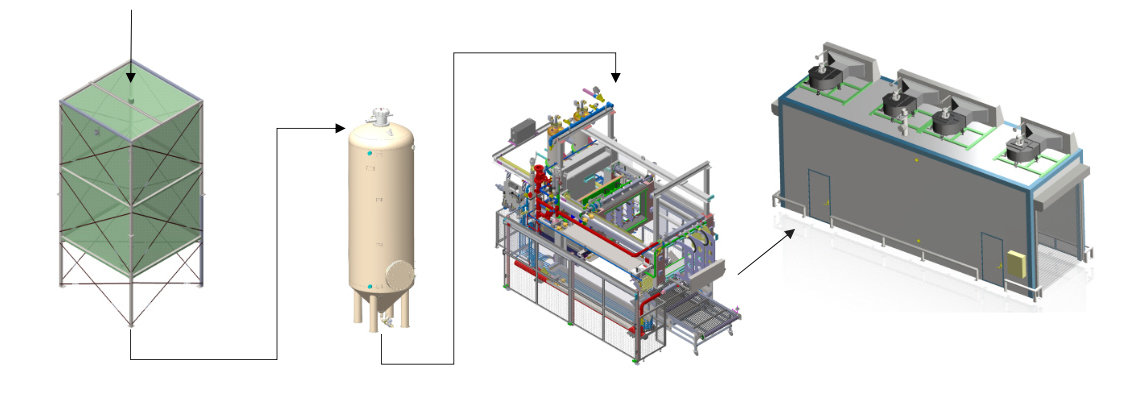

SILO PLANT

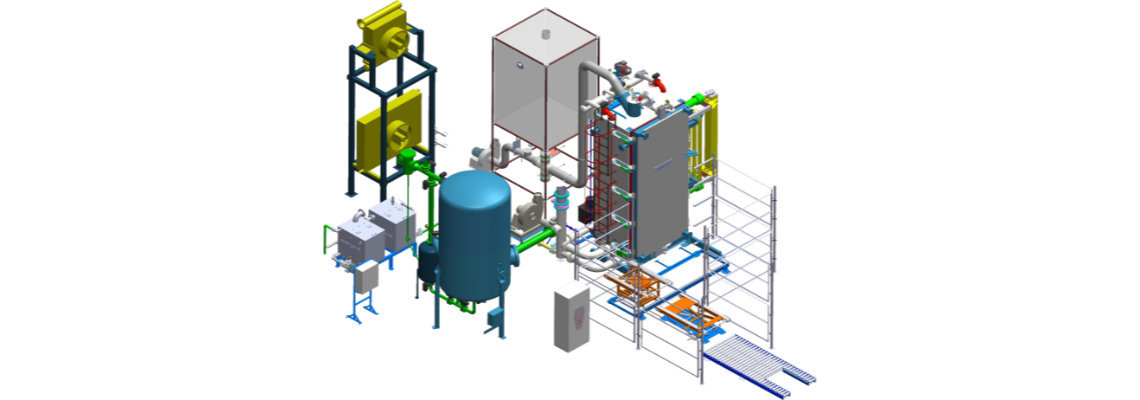

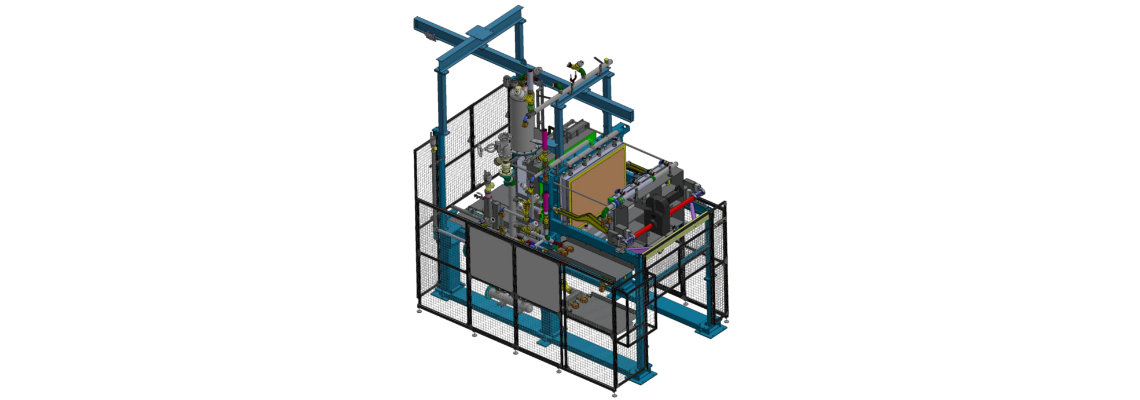

BLOCK MOULD

PRODUCTION OF EPS BLOCKS

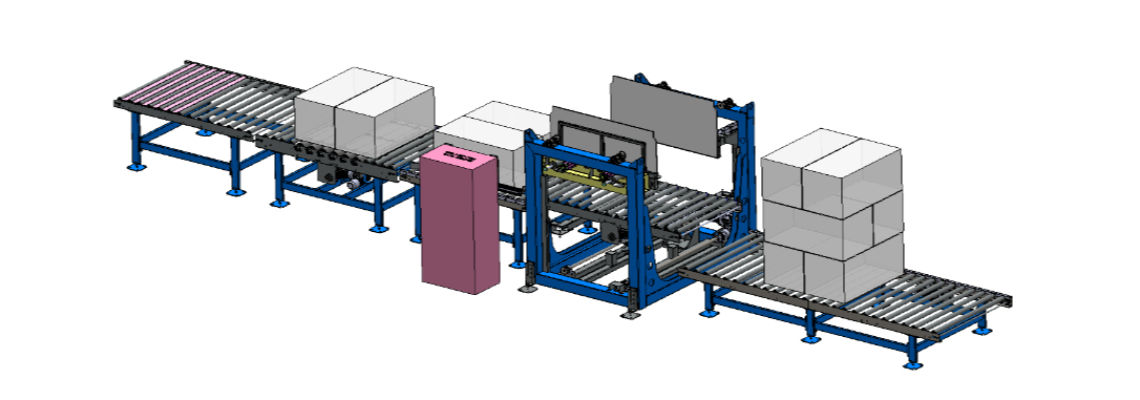

CUTTING LINE

PACKAGING STATION

PACKAGING LINE

EPS VACUUM PREEXPANDER

SHAPE MOULDING MACHINE EPS OR EPP

PRODUCTION OF MOULDED EPS PARTS

TEMPERING OF EPP PARTS

PRODUCTION OF MOULDED EPP PARTS

Machinery for processing particle foams (foamable polymers): expandable polystyrene (EPS, ‘Styropor’, XPS), expandable polypropylene (EPP), expandable polyethylene (EPE) is our task.

We have more than 20 years of experience in the planning, delivery, installation and start up of machines and complete plants for the manufacture of products from polymer particle foams.

Technical support for our customers in their daily work processes is also a matter of course for us. We do not see ourselves primarily as a supplier, but as a friendly partner to our customers.

Our energy and commitment is channeled into both large and small projects.

Thank you for visiting our website to get a first impression of our field of activity and previous projects.

Please do not hesitate to contact us if you are interested.

Machinery for Particle Foams

News

21 Feb. 2024

New Used Market section expands our web presence with instant effect. With this new section, we are responding to the wishes of our customers. We believe that our extensive expertise will enable us to better serve the particle foam processing market.

Visit us often, together we are strong.

Project Management

From the preparation of the quotation to the production of the plant to the installation and commissioning – we accompany our customers through all aspects of the project. Even afterwards, we support our partners in questions of maintaining quality, maintenance and installation upkeep.

The size of the plant and / or project does not matter. We are equally committed to all customer concerns with our utmost dedication and intelligent project management.

Everything

for

expandable

polystyrene

and

expandable

polypropylene

Our first priority is the integrity of the plant or new machines for particle foam in your production process. Therefore, a decisive sub-process of operational planning is requirements management. This makes it clear at the outset whether the customer only needs a new mould or a complete machine.

Of course, we take care of the monitoring of performance, economic efficiency, etc. Our dialogue starts as a simple consultation and, according to our experience, very often turns into a long-term and friendly cooperation.

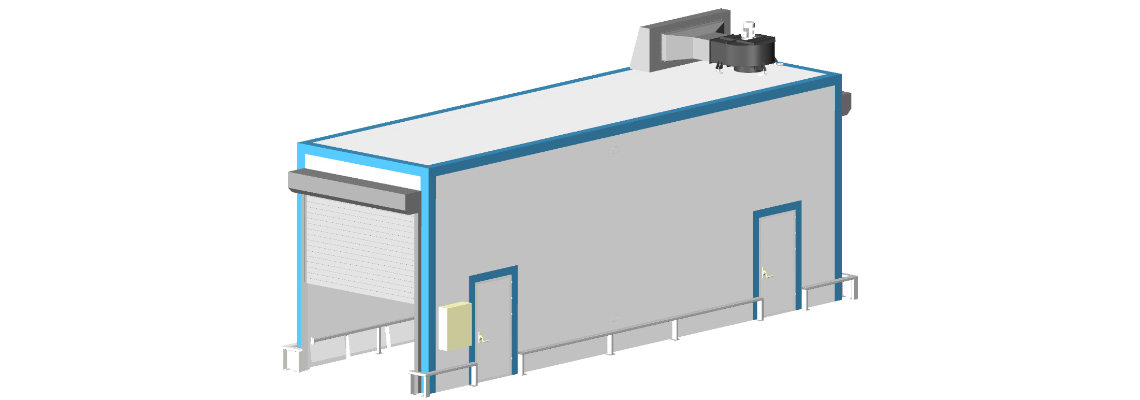

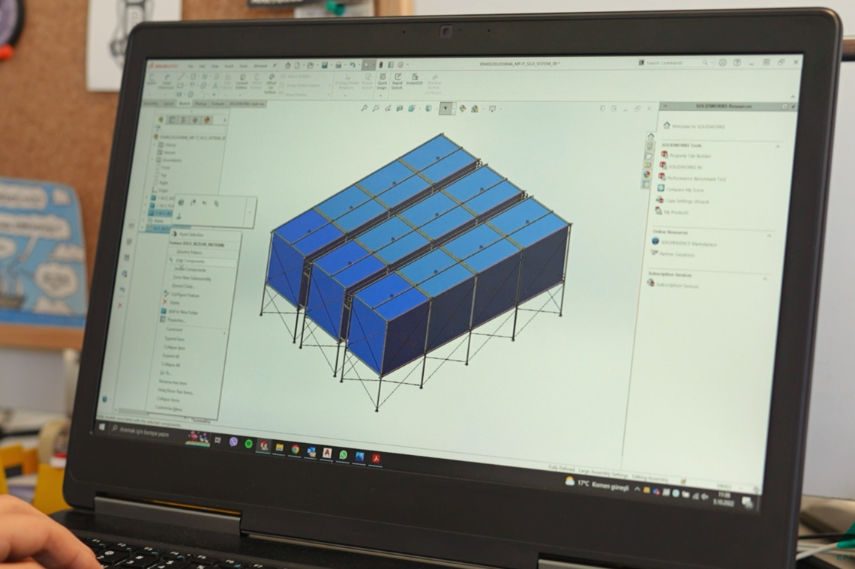

Projects are first modelled on the computer and then implemented, connected and integrated using drawings, layouts, profitability calculations, built machines and systems.

Project Planning of Plants for Particle Foams

An installation including the connections of the energy media, the pipework and the raw material flow can quickly become a problem without sound experience and knowledge, especially in systems that are subject to official supervision.

Our reference projects show that we have built up a competent knowledge base in all these matters and are therefore highly innovative.

Installation and StartUp

Everything

for

expandable

polystyrene

and

expandable

polypropylene

Customer-oriented financing is always an important component of our customer service. Whether it is a supplier credit or a leasing transaction, we always help to find an optimal solution concept. In doing so, we rely on our many years of experience, which we have gained through our numerous reference projects.

But our constant contact with banks and the network we have built up as a result also help us to stay “fit” in these matters and to be able to offer you a superior overall concept.